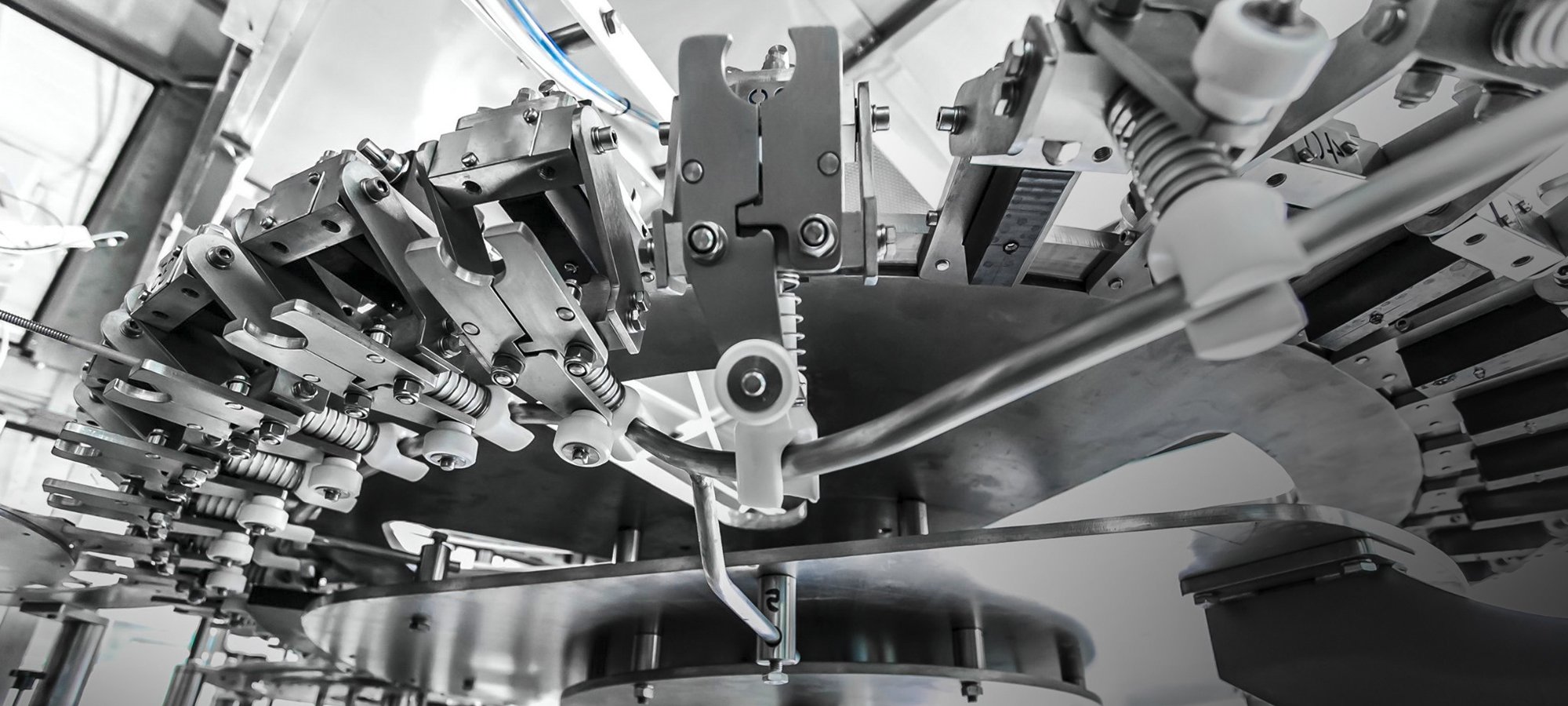

Water Filling Machine

For some companies or manufacturers, using the automatic water filling machine instead of the manual work is a big trend of water bottling industry.

Automatic Water Filling Machine for Sale

As a professionable manufacturer and supplier, Famous Machine specializes in the packaging industry and offer a wide selection of automatic water filling machines at reasonable price. Our products have several features like a PLC system, touchscreen interface and several containers of different shapes and sizes. You’ll find 3-in-1 washing filling capping machine as well as bottle labeling machine for your complete water bottle packaging line here.

Liquid Filling Technologies for Water Bottles

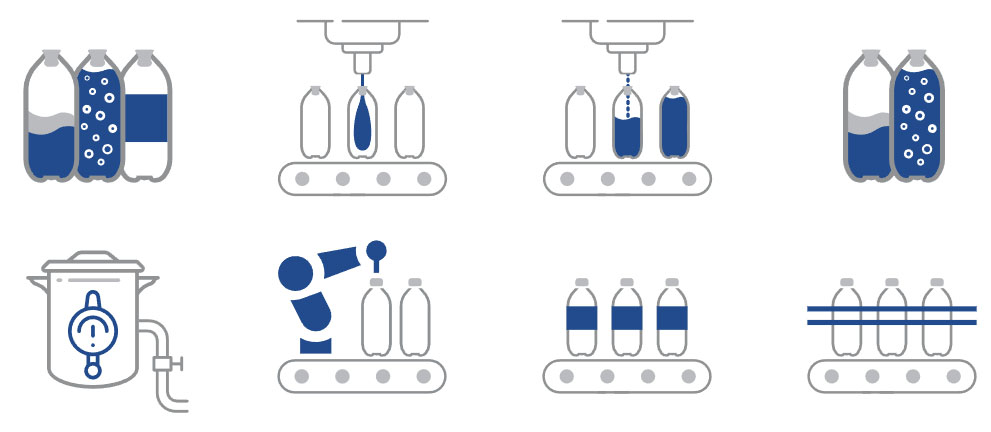

FMS Machine offers large collection of liquid filling machines with various filling technologies. These filling technologies are applicable to fill for liquid various viscosities. Since water has a very low viscosity, you should choose the right machinery for your water bottle filling line. The following filling machines are recommended for water bottles:

Mechanical gravity filter

For low viscosity liquid such as water, juice and wine, gravity filling machines are one of the best options for your production line.

Flow meter filter

Flow meter filling machines are best for liquids like water, juice, CSD and wine. This filter can be used for juice filling machine or wine filling machine.

Vacuum filter

Vacuum filling machines are an option for low and medium viscosity liquids such as water, juice, wine and condimen.

Weighing filter

Weight filling machines are suitable for large container filling applications. These filters are one of options for water or juice bottle filling line.

Benefits of Automatic Liquid Filling Machinery for Water Bottles

Famous Machine offers a wide range of machinery solutions capable of filling for low-viscosity liquids such as water with the bottle shape like PET circular or square. The following are the benefits of installation of a liquid filling machine in your assembly line.

Higher Productivity

Higher Productivity is an important goall of beverage companies. The machine has adjustable speed limits to increase and decrease the speed as and when required. The production can be regulated as per demand forces in the market, leading to higher productivity.

Cost-effective and time-saving

Purchasing water filling machines is a high investment, but it is the best strategy to reduce labor and time costs. The companies can focus on more fruitful sources of the business without time waste.

Looking for water bottling machine products for your project? Contact us today for a quick quote.

Liquid Filling Technologies for Water Bottles

FMS Machine offers large collection of liquid filling machines with various filling technologies. These filling technologies are applicable to fill for liquid various viscosities. Since water has a very low viscosity, you should choose the right machinery for your water bottle filling line. The following filling machines are recommended for water bottles:

Mechanical gravity filter

For low viscosity liquid such as water, juice and wine, gravity filling machines are one of the best options for your production line.

Flow meter filter

Flow meter filling machines are best for liquids like water, juice, CSD and wine. This filter can be used for juice filling machine or wine filling machine.

Vacuum filter

Vacuum filling machines are an option for low and medium viscosity liquids such as water, juice, wine and condimen.

Weighing filter

Weight filling machines are suitable for large container filling applications. These filters are one of options for water or juice bottle filling line.

Benefits of Automatic Liquid Filling Machinery for Water Bottles

Famous Machine offers a wide range of machinery solutions capable of filling for low-viscosity liquids such as water with the bottle shape like PET circular or square. The following are the benefits of installation of a liquid filling machine in your assembly line.

Higher Productivity

Higher Productivity is an important goall of beverage companies. The machine has adjustable speed limits to increase and decrease the speed as and when required. The production can be regulated as per demand forces in the market, leading to higher productivity.

Cost-effective and time-saving

Purchasing water filling machines is a high investment, but it is the best strategy to reduce labor and time costs. The companies can focus on more fruitful sources of the business without time waste.

Looking for water bottling machine products for your project? Contact us today for a quick quote.

At Famous we offer solutions for producing high quality bottled water with a minimal environmental and cost impact. Sustainable bottled water production requires the utmost attention to hygienic conditions and product quality, as well as optimisation of production output to achieve maximum appeal at minimum cost.

For bottled water, appealing bottle design and product quality are key factors to win on the shelves, as consumers demand unique bottle shapes with a premium feel and look that exceeds the quality of tap water. At the same time, bottle lightweighting is needed to reduce the environmental impact and cost of bottling operations. Our bottle design expertise helps to find the RightWEIGHT™ balance between appeal and material use. We are committed to offering our expertise and services to improve and support your water line performance.

Every food and beverage production needs to accommodate diverse capacity and flexibility requirements. Whether you're entering new product categories, seeking increased flexibility or aiming to ramp up production, our diverse selection of filling machines for aseptic, chilled, and food production provides flexible and cost-effective solutions, ensuring your business remains agile and efficient.

Linear Filling machine MP 6-2.B.L.02 is designed for water filling and suitable for PET bottles with the volume up to 10L. Working speed of this filler is 1000 bph of 5L. This machine is built of two modules – for water filling (with four filling nozzles) and capping (with one capping head).

What is more, we pride ourselves in creating eco-friendly PET technology. Our standard PET bottle machine, or as others call it – PET blow moulding machine, PET blow molding machine, PET blow machine or blowing machine – can be easily fitted with which makes energy saving so much easier. Contact us and we will help you choose all the equipment needed for you to start working on your new complete filling line.