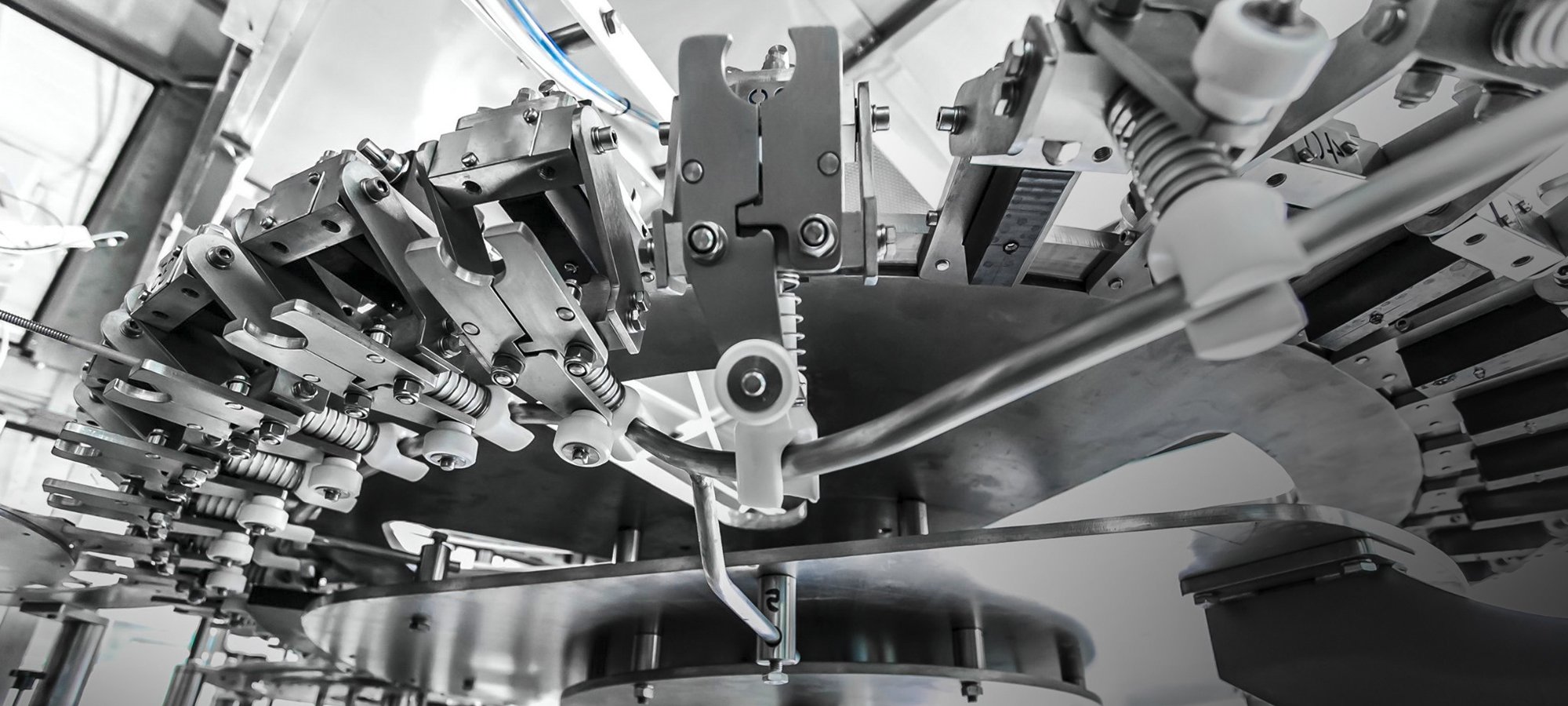

The series equipment is used for hot filling and sealing of green tea, black tea, wulong tea and fruit juice. The machine integrates washing, filling, capping together. The design is scientific and reasonable. Its appearance is beautiful. Its operation and maintenance is convenient. The automation is high. It is good equipment for choosing hot drink filling machine.

This series machine is adopt block bottle-neck hanging work state design, and be adopt filling valve rise-drop design, It's be satisfy for 95 degree hereinafter hot filling technology demand.

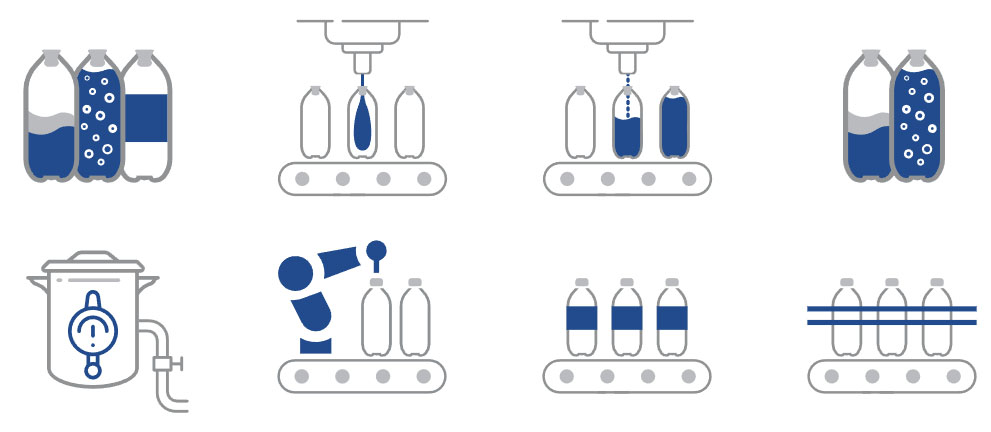

1.washing,filling capping 4in1 machine is mainly used in the juice with pulp hot filling operations.

2.The four functions of bottle rinsing,pulp filling and juice filling and capping are composed in one body of the machine.

3.The machine is used in filling juice drinks, juice with pulp drinks, basil seed juice drinks in glass bottles.

4.The advanced SIEMENS programmed controller (PLC) ,It is convenient to operate with higher automation

Features:

1) Compact conformation, good shape, cozy operation, excellent automaticity and poor labor intensity.

2) Only exchanging "star wheel", "feeding screw" and "arc guide plate" is needed while exchanging model of bottle.

3) The all parts directly contacted with material are all adopted with food stage stainless steel without dead angle, so they can be cleaned easily.

4) Adopting advanced valve to control the inlet flow rate of liquid.

It can keep the slight turbulence of liquid level in the solution barrel and ensure the accuracy in filling.

5) Closing feeding valve automatically while no bottle on machine avoid the loss of aqueous feet.

Filling automatically is with a high speed and the control of liquid level is accurate.

6) The magnetic-constant-torque device is adopted in capping head to ensure the high capping quality without damage.

7) Adopting efficient cap settling system which carried perfect cap feeding and protection device.

8) It is adopted spiral descent fashion for the support plate for bottom of bottle at the outlet thumb wheel.

And to adjust the input height is not necessary for exchanging model of bottle.

9) carried the perfect protection system to overload; It can be used to protect facilities and operators efficiently.

10) Because of applying touch screen for operation, it is possible to realize man-machine

Conversation whereas the status of device running is clear at a glance.

11) The primary electric components such as touch screen\PLC\transducer etc. Are all adopted with well known import products.

Containers and Specifications |

||||

Project Name: Full Automatic Complete Juice(Fruit)Pulp 2000-20000bph Production Line |

Hot Filling Fruit Juice |

|||

Material |

Shape |

Filling volume |

Filling level |

Neck type |

Glass Bottle |

Square or Round |

100-2000ml |

Distance from bottle neck According request |

As request |

Adjustable specifications of the bottle type |

【Middle Mould Base】Bottle diameter ≤105mm Bottle Height≤335mm |

|||

Customers need to buy additional change-over parts for the different bottles. |

||||

Juice Preparation |

Fruit , Concentrate, Powder mixing, Pulp size≤15mm ..... |

|||

Container Label & Control Mode |

Packaging system |

Palletizing system |

||

Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automatic |

Packing system |

Min, Spec. |

Manual Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer |

|

Manual Film shrinker Wrap Around packe Robert Packing Machine |

1*2 2*3 3*4 4*6 3*5 |

|||

User Ambient Conditions: |

Temperature:10~40℃;Humidity:No dew |

|||

User Electrical Supply Specification |

Voltage:380V±5%, 3phase; Frequency:50HZ±1% |

|||

Features:

1) Compact conformation, good shape, cozy operation, excellent automaticity and poor labor intensity.

2) Only exchanging "star wheel", "feeding screw" and "arc guide plate" is needed while exchanging model of bottle.

3) The all parts directly contacted with material are all adopted with food stage stainless steel without dead angle, so they can be cleaned easily.

4) Adopting advanced valve to control the inlet flow rate of liquid.

It can keep the slight turbulence of liquid level in the solution barrel and ensure the accuracy in filling.

5) Closing feeding valve automatically while no bottle on machine avoid the loss of aqueous feet.

Filling automatically is with a high speed and the control of liquid level is accurate.

6) The magnetic-constant-torque device is adopted in capping head to ensure the high capping quality without damage.

7) Adopting efficient cap settling system which carried perfect cap feeding and protection device.

8) It is adopted spiral descent fashion for the support plate for bottom of bottle at the outlet thumb wheel.

And to adjust the input height is not necessary for exchanging model of bottle.

9) carried the perfect protection system to overload; It can be used to protect facilities and operators efficiently.

10) Because of applying touch screen for operation, it is possible to realize man-machine

Conversation whereas the status of device running is clear at a glance.

11) The primary electric components such as touch screen\PLC\transducer etc. Are all adopted with well known import products.

Containers and Specifications |

||||

Project Name: Full Automatic Complete Juice(Fruit)Pulp 2000-20000bph Production Line |

Hot Filling Fruit Juice |

|||

Material |

Shape |

Filling volume |

Filling level |

Neck type |

Glass Bottle |

Square or Round |

100-2000ml |

Distance from bottle neck According request |

As request |

Adjustable specifications of the bottle type |

【Middle Mould Base】Bottle diameter ≤105mm Bottle Height≤335mm |

|||

Customers need to buy additional change-over parts for the different bottles. |

||||

Juice Preparation |

Fruit , Concentrate, Powder mixing, Pulp size≤15mm ..... |

|||

Container Label & Control Mode |

Packaging system |

Palletizing system |

||

Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automatic |

Packing system |

Min, Spec. |

Manual Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer |

|

Manual Film shrinker Wrap Around packe Robert Packing Machine |

1*2 2*3 3*4 4*6 3*5 |

|||

User Ambient Conditions: |

Temperature:10~40℃;Humidity:No dew |

|||

User Electrical Supply Specification |

Voltage:380V±5%, 3phase; Frequency:50HZ±1% |

|||

At Famous we offer solutions for producing high quality bottled water with a minimal environmental and cost impact. Sustainable bottled water production requires the utmost attention to hygienic conditions and product quality, as well as optimisation of production output to achieve maximum appeal at minimum cost.

For bottled water, appealing bottle design and product quality are key factors to win on the shelves, as consumers demand unique bottle shapes with a premium feel and look that exceeds the quality of tap water. At the same time, bottle lightweighting is needed to reduce the environmental impact and cost of bottling operations. Our bottle design expertise helps to find the RightWEIGHT™ balance between appeal and material use. We are committed to offering our expertise and services to improve and support your water line performance.

Every food and beverage production needs to accommodate diverse capacity and flexibility requirements. Whether you're entering new product categories, seeking increased flexibility or aiming to ramp up production, our diverse selection of filling machines for aseptic, chilled, and food production provides flexible and cost-effective solutions, ensuring your business remains agile and efficient.

Linear Filling machine MP 6-2.B.L.02 is designed for water filling and suitable for PET bottles with the volume up to 10L. Working speed of this filler is 1000 bph of 5L. This machine is built of two modules – for water filling (with four filling nozzles) and capping (with one capping head).

What is more, we pride ourselves in creating eco-friendly PET technology. Our standard PET bottle machine, or as others call it – PET blow moulding machine, PET blow molding machine, PET blow machine or blowing machine – can be easily fitted with which makes energy saving so much easier. Contact us and we will help you choose all the equipment needed for you to start working on your new complete filling line.