Plastic Handle Mold with Hot Runner for 5 Liter Bottle, Huangyan Famous Moldis a professional China Cap mould Manufacturers and China Cap mould suppliers. We stick to the principal of quality orientation and customer priority, we sincerely welcome your letters, calls and investigations for business cooperation.

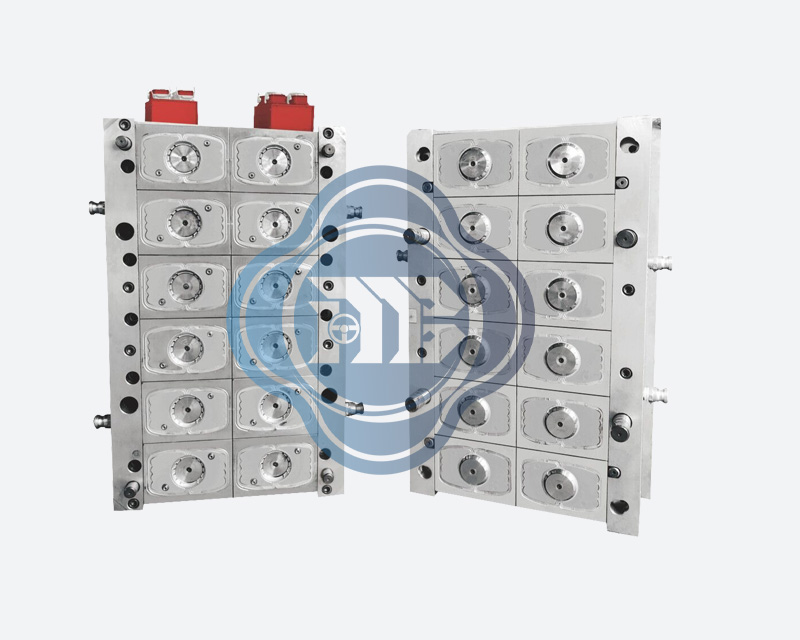

Product Details:24 cavities plastic handle mold with hot runner for 5 Liter bottle

Being one of the renowned organizations in the industry, we are providing our clients with a unique range of Handle Cap Mould.

Looking for high quality Plastic Cap Mould with excellent service? Leave your message here to tell us your idea or requirement, one of our professional engineers would give quick back to you. It would be a start of a long relationship between us.

1.MOULD MANUFACTURE PROCESS

Cap mould: grinding--fly cutter--CNC Milling --Drilling --Lathe --Boring lathe --electric pulse --Finishing CNC -- EDM --Polishing --Installing -- Testing3.Interchangeable parts for every cavity.

2.BUSINESS STEPS

1. R&D We support customers R&D. We will make the files or improve the design if you need

2. Quotation Making mould quotation will be finished in 1 or 2 days according to the drawing & sample which you supplied.

3. Negotiation The negotiation includes quality, price, material,delivery time,payment term,ect.

4. Mould Design We need to spend 3-5 days on mould and product 3D/2D drawing design.

5. Mould We will build the mould based on customers's requirements. Before making the mold, we will send mold design to the customers for approval firstly.

6. Mould Testing When mold is finish, we will test the mold to check if the product will be satisfied with customer's requirements, and we will send samples to the customers for approval.

7. Delivery We will delivery the goods to the customers either by sea or by air.

Product packaging and transportation:

The outer packing with wooden cases by sea transportation.

After-sales service of products:

Our technician can be the buyer’s factory to install and run the mould. But the buyer should bear all the cost for the technician’s trip(include the air ticket, the cost of the accommodation and the salary)

Delivery details:

THE DATE OF DELIEVERY: 35-45 DAYS AFTER GETTING THE DEPOSIT.

THE PORT OF DELIEVERY: NINGBO,CHINA

| Mould cavity | S136 from Sweden ASSAB with HRC 50-52 |

| Mould core | S136 from Sweden ASSAB with or M310 from Austria with HRC 52-55 |

| Mould core sleeve | DC11 from Japan or W302 from Austria with 60-62HRC |

| Core Central Ejector | Beryllium Copper + Chroming treatment with HRC 62-64 HRC |

| Ejector way | Ejector plate+ Ejector sleeve |

| Mould Manifold plate | H13 from America for hot runner mold. |

| Mould other plate | P20 |

| Hot runner system | hot runner |

| Free spare parts of mould | Core set : 1set/ cavity: 1 Piece/ hot runner system:1set/PID controller system: 1Set/ other easy broken spare parts for each 8 cavities cap mould. |

| Gurantee of the mould | 1 year or 1 million shot times(in this period, if the mold have problem, we will offer the parts or service by free, but not include the problems cased by wrong operation) |

| The life of the mould | 5-6 years, Even in 10 years in good maintenance |

| Installation & Commission | Our technician can be the buyer's factory to install and run the mould. But the buyer should bear all the cost for the technician's trip(include the air ticket, the cost of the accommodation and the salary) |

| Remark: Our mould different part will used different material. All the material was important and special for making cap mould. The mould material choice can make sure the mould action and mould running life | |

With over a decade of manufacturing experience in the automatic cap molds industry, we are confident with our high-quality products helping you achieve your company goals. Allow Shuanghao molds to supply your bottle cap molds requirements and experience the superior difference with our advanced equipment.

Our company offers customized services for bottle cap molds, allowing us to design and manufacture the most efficient molds based on your industry requirements.

Advanced Equipment:We have a range of top-notch CNC machines, such as EDMmachine, carving machine, and other high precision machining equipment. They ensure full numerical control, high efficiency, and precise manufacturing of key parts.

Rich Experience:

Famous mould is your reliable mould manufacturer. We have been focusing on various kinds of plastic cap and handle molds for about 20 years.

Comprehensive Range:

Our range includes CSD water cap molds, 5-gallon cap molds, sports cap molds, beverage cap molds for juice and milk, flip-top cap molds, cosmetic cap molds, and more.

A cap mold, also known as a cap mould, is a specialized mold used in the manufacturing process of caps or closures for bottles, containers, or other packaging products. It is designed to create the specific shape, size, and features of the cap, such as the threads, tamper-evident bands, and sealing mechanisms.