Bottle lid molds, also known as bottle cap molds, are an essential tool in the production of plastic bottle caps. These molds are designed to create a variety of cap designs that are both functional and visually appealing. Here are some of the key features of bottle lid molds:

1. Precision - Bottle lid molds are crafted to exact specifications, ensuring that each mold produces uniform caps that fit securely on bottles.

2. Durability - These molds are made from high-quality materials, such as stainless steel or aluminum alloy, that can withstand high temperatures and repeated use without wearing down.

3. Versatility - Bottle lid molds can be designed to produce caps of various shapes, sizes, and materials to meet different production needs and customer preferences.

4. Customization - Manufacturers can personalize bottle lid molds with unique designs, logos, or text, making the finished product stand out and enhancing brand recognition.

5. Cost-effectiveness - Due to their precision and durability, bottle lid molds offer a cost-effective solution for producing high-quality bottle caps in large quantities.

Overall, bottle lid molds are an essential component in the production of plastic bottle caps, providing manufacturers with efficient and reliable means of producing high-quality caps with unique designs and superior functionality.

Bottle lids mold is an essential tool for producing high-quality bottle caps and lids, which are widely used in the beverage, home care, and personal care industries. With advanced technology and precision engineering, this mold ensures consistent and accurate molding of bottle caps, making them perfect for sealing and protecting various types of products.

The mold is made with high-quality materials that are durable and resistant to wear and tear. It also has a user-friendly design that makes it easy to use and maintain. With regular cleaning and maintenance, the bottle lids mold can last for many years, providing excellent value for money.

Furthermore, this mold comes in different sizes and shapes, making it suitable for different types of bottles and lids. It is also customizable, ensuring that manufacturers can produce caps that meet their specific needs and requirements.

Overall, the bottle lids mold is a crucial tool for the production of high-quality bottle caps and lids. Its precision and reliability make it an indispensable component of the manufacturing process, helping to ensure the quality and safety of the products.

With over a decade of manufacturing experience in the automatic cap molds industry, we are confident with our high-quality products helping you achieve your company goals. Allow Shuanghao molds to supply your bottle cap molds requirements and experience the superior difference with our advanced equipment.

Our company offers customized services for bottle cap molds, allowing us to design and manufacture the most efficient molds based on your industry requirements.

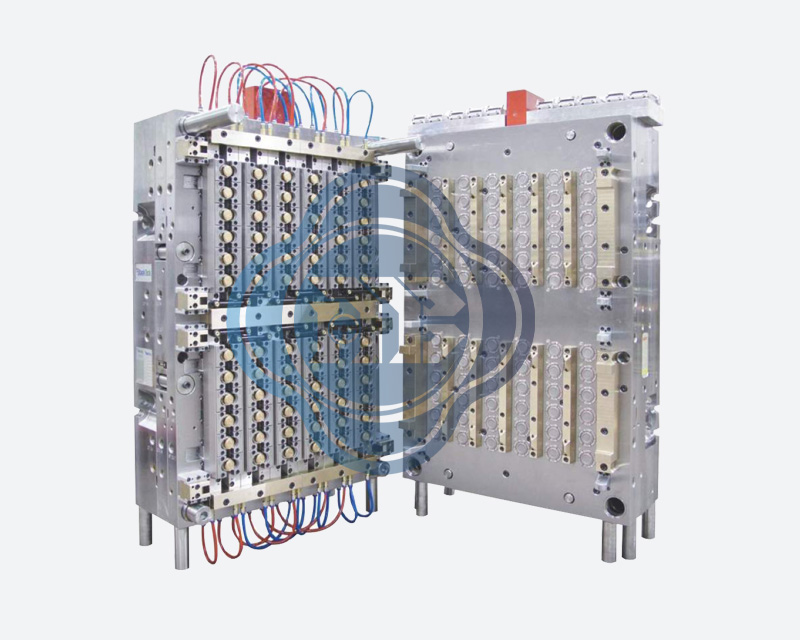

Advanced Equipment:We have a range of top-notch CNC machines, such as EDMmachine, carving machine, and other high precision machining equipment. They ensure full numerical control, high efficiency, and precise manufacturing of key parts.

Rich Experience:

Famous mould is your reliable mould manufacturer. We have been focusing on various kinds of plastic cap and handle molds for about 20 years.

Comprehensive Range:

Our range includes CSD water cap molds, 5-gallon cap molds, sports cap molds, beverage cap molds for juice and milk, flip-top cap molds, cosmetic cap molds, and more.

A cap mold, also known as a cap mould, is a specialized mold used in the manufacturing process of caps or closures for bottles, containers, or other packaging products. It is designed to create the specific shape, size, and features of the cap, such as the threads, tamper-evident bands, and sealing mechanisms.